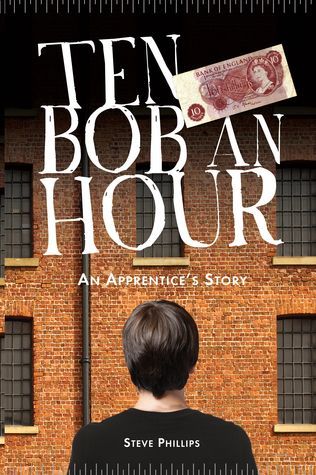

Ten Bob an Hour

When Steve Phillips started as a 15-year-old apprentice with a Birmingham engineering company in 1961, the Beatles were still the Quarrymen and a pint of mild cost one shilling and three pence. Five years of dirt and grind, leg pulls, laughter and sheer hard graft later, Steve was a skilled turner and fitter, schooled the old fashioned way by senior craftsmen who knew how to turn a screw, mill a die or grind a component to half a thousandth of an inch using manually-controlled machine tools, a micrometer and the skill in their fingers. He had also found the time – and saved the money - to marry his teenage sweetheart and buy a house.Steve went on to a varied and successful career in the manufacturing industry. Half a century on, now retired and living in Cyprus, he looks back on an era before computers and CNC machines, when Birmingham and its factories were the backbone of industrial Britain and families and workmates stuck together. Ten bob an hour is a fascinating portrait of an era long gone.Steve says 'Fifty years ago, a 15-year-old Brummie school-leaver called Stephen Phillips walked into the reception area of a big Midland manufacturing company to start an apprenticeship in engineering. That was me. I hadn’t a clue what was coming – the dirt and grind, the hard work and the long hours, the leg pulls and laughter, the comradeship and the slow graduation from greenhorn to skilled man. The next five years would prove arduous, difficult and dirty, but at the end of it all, thanks largely to some of the best mates and colleagues I ever had, I managed to emerge a trained and qualified engineer on the ‘holy grail’ pay rate of ‘ten bob an hour’ – that’s 50p in today’s coinage. It doesn’t sound like much, but it was a lot of money in those days. It certainly seemed like it.This book is about those never-to-be forgotten years'.